Football ⚽

Kraftoll Cutting Boards deliver unmatched precision and durability in the manufacturing of football panels. Their resilient surface ensures clean, uniform cuts, while extending the life of dies and presses. Designed for heavy-duty sports goods applications, Kraftoll boards provide consistent performance even under high production volumes, helping manufacturers maintain quality standards while reducing downtime and costs.

Key Features:

- Exceptional wear resistance for long service life

- Elastic, self-healing surface reduces die damage

- Superior flatness for precise hexagon/pentagon panel cutting

- High impact absorption prevents press bed damage

- Uniform cutting depth across the board surface

- Easy to re-plane and reuse, maximizing cost efficiency

- Stable performance under continuous high-speed production

- Low maintenance with reduced scrap and waste

- Trusted German-engineered quality for sports industry

Meat Cutting 🥩

Kraftoll Cutting Boards provide the highest level of hygiene, strength, and durability for meat and poultry processing. Their smooth, food-safe surface guarantees clean cuts, reduces contamination risk, and withstands the rigors of heavy chopping, portioning, and processing. Designed for demanding food industry environments, Kraftoll boards combine long service life with easy maintenance, ensuring safety and efficiency on every cut.

Key Features:

- Certified food-grade surface for safe contact with meat

- Exceptional wear and cut resistance for heavy-duty use

- Hygienic, non-porous structure — resists bacteria absorption

- Smooth, easy-to-clean surface supports strict sanitation standards

- Superior flatness ensures uniform cutting and portioning

- Durable under repeated knife impact and pressure

- Resistant to stains, odors, and moisture penetration

- Long-lasting performance, reducing replacement costs

- Available in multiple colors for HACCP compliance and segregation

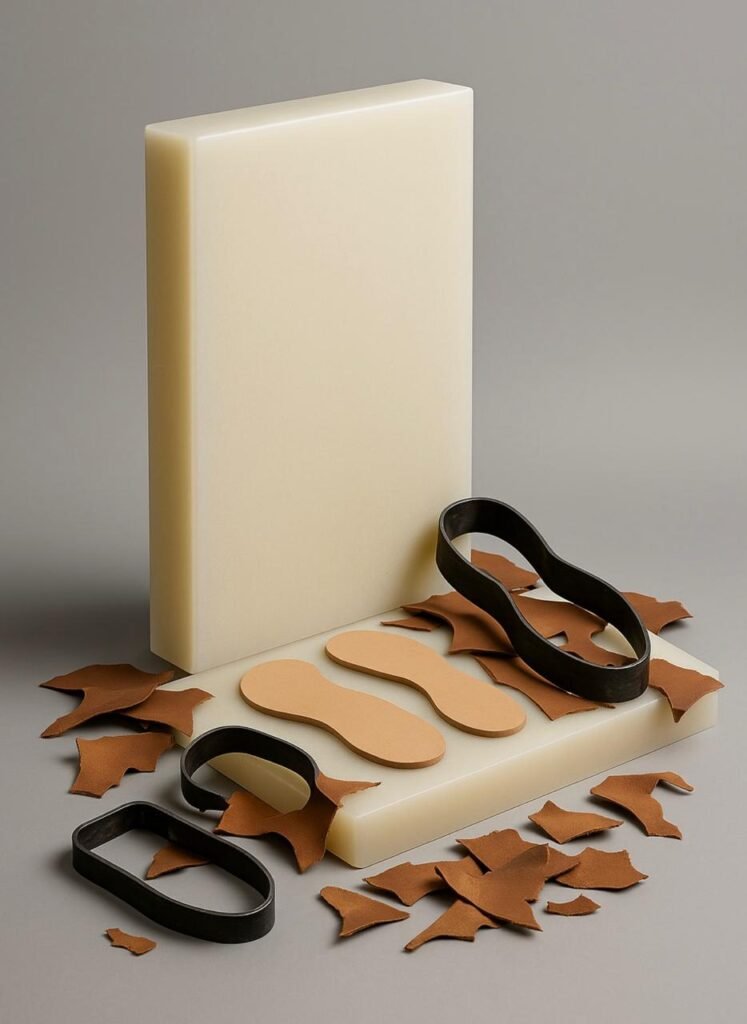

Shoe Sole Cutting 👞

Kraftoll Cutting Boards deliver unmatched precision and resilience in leather footwear manufacturing, especially for shoe sole cutting. Their elastic yet durable surface ensures clean die penetration, protecting expensive cutting tools while maintaining consistent quality across every batch. Trusted by the leather industry, Kraftoll boards are engineered for long service life, reduced downtime, and superior productivity.

Key Features:

• High impact absorption — protects both press and dies

• Elastic recovery (“self-healing”) for longer board life

• Superior flatness guarantees consistent cutting depth

• Excellent wear resistance under continuous heavy-duty use

• Smooth surface prevents leather tearing or distortion

• Easy to re-plane and reuse, reducing operating cost

• Stable under repetitive high-pressure cutting cycles

• Long-lasting German-engineered quality, proven in footwear industry

• Minimizes scrap and ensures uniform shoe sole dimensions

Gloves Cutting 🧤

Kraftoll Cutting Boards are engineered to deliver precise and efficient performance in the cutting of leather, safety, and sports gloves. Their resilient and self-healing surface allows clean penetration of dies, maintaining sharpness and extending tool life. Designed for high-cycle press operations, Kraftoll boards ensure consistency, minimize waste, and withstand the demanding conditions of glove manufacturing.

Key Features:

• Elastic recovery surface for long-lasting durability

• Superior flatness ensures accurate cutting of glove patterns

• Excellent wear resistance under continuous press cycles

• High impact absorption protects press beds and dies

• Clean, uniform cuts reduce rejects and scrap

• Easy to re-plane and reuse, extending board life

• Stable under high-pressure and repetitive operations

• Compatible with leather, synthetic, and technical fabrics

• German-engineered reliability trusted in global glove industries

Vegetable Cutting 🥒

Kraftoll Cutting Boards are the ideal choice for vegetable and fruit processing, ensuring hygiene, durability, and clean slicing in food production environments. Their smooth, non-porous, food-safe surface resists bacteria absorption and provides consistent cutting results under continuous use. Designed to meet the highest food industry standards, Kraftoll boards combine safety, longevity, and efficiency in every operation.

Key Features:

• Certified food-grade and hygienic for fresh produce handling

• Non-porous surface prevents bacteria, stains, and odors

• Exceptional wear resistance for long-lasting performance

• Smooth surface ensures precise and clean slicing of vegetables

• Easy to sanitize and maintain under strict HACCP standards

• Superior flatness for uniform cutting across the entire surface

• Resistant to moisture and knife impact damage

• Available in multiple colors for cross-contamination control

• German-engineered quality trusted in global food industries